News

how to electropolish stainless steel?

how to electropolish stainless steel? Stainless steel electrolytic polishing liquid: Choose the electrolytic polishing liquid suitable for stainless steel, and select the appropriate polishing liquid ···

how to electropolish stainless steel?

[ Data:2024-01-02 View:109Times ]

First. material preparation

Before electrolytic polishing of stainless steel, we need to prepare the following materials:

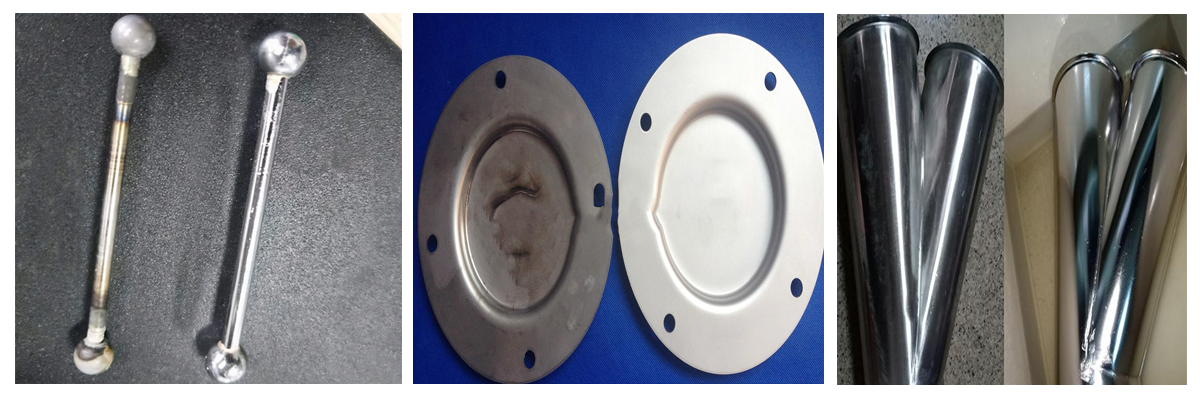

Stainless steel workpiece: stainless steel workpiece that needs to be polished.

Stainless steel electrolytic polishing liquid: Choose the electrolytic polishing liquid suitable for stainless steel, and select the appropriate polishing liquid concentration according to the requirements of the workpiece.

Electrolyzer: A container for placing polishing fluid and workpieces.

Power supply: Used to provide electrical energy for electrolytic polishing.

Wire brush: used to clean the surface of stainless steel workpiece.

Second. Preparation

Cleaning the workpiece: Use a wire brush to clean the surface of the stainless steel workpiece, remove the dirt and oxidation layer on the surface, and ensure that the surface is clean.

Prepare the electrolytic cell: clean the electrolytic cell, pour the appropriate amount of polishing liquid, the liquid level should be high enough for the workpiece to soak in it.

Connect the power supply: Connect the power supply to the electrolyzer to ensure that the power supply works properly.

Third. electrolytic polishing

Workpiece placement: Place the cleaned stainless steel workpiece into the electrolytic cell and ensure that the workpiece is completely immersed in the polishing liquid.

Set current density: According to the requirements of the workpiece and the concentration of the polishing liquid, set the appropriate current density. Typically, the current density is between 1-20A/dm².

Start electrolysis: Turn on the power and start electrolytic polishing. During the polishing process, the workpiece should be kept stable to avoid shaking or colliding with other metal objects.

Polishing time control: According to the requirements of the workpiece and the concentration of polishing fluid, control the polishing time. Usually, the polishing time is between a few minutes and tens of minutes.

Observe the polishing effect: In the polishing process, you can timely observe the polishing effect of stainless steel workpiece. If you need better results, you can appropriately extend the polishing time.

End electrolysis: When the polishing time reaches the requirement, turn off the power to finish electrolytic polishing.

Cleaning the workpiece: remove the polished stainless steel workpiece, rinse it with water, and remove the polishing liquid and residue.

Drying workpiece: dry the cleaned stainless steel workpiece or use a hair dryer and other methods to accelerate drying.

Fourth. Precautions

Safe operation: When electrolytic polishing stainless steel, pay attention to safe operation to avoid electric shock or other accidents

Appropriate adjustment parameters: According to the requirements of different workpieces and the concentration of polishing fluid, the current density and polishing time are adjusted appropriately to obtain the best polishing effect.

Prevent over-polishing: control the polishing time to avoid excessive removal of stainless steel surface materials caused by too long polishing, causing deformation or damage to the workpiece.

Regular replacement of polishing fluid: stainless steel electrolytic polishing fluid will deteriorate with the increase of use time, affecting the polishing effect, so it is necessary to replace the polishing fluid regularly.

Storage of electrolyzer and polish: Electrolyzer and polish should be stored in a dry, ventilated place, away from direct sunlight and high temperature environment.